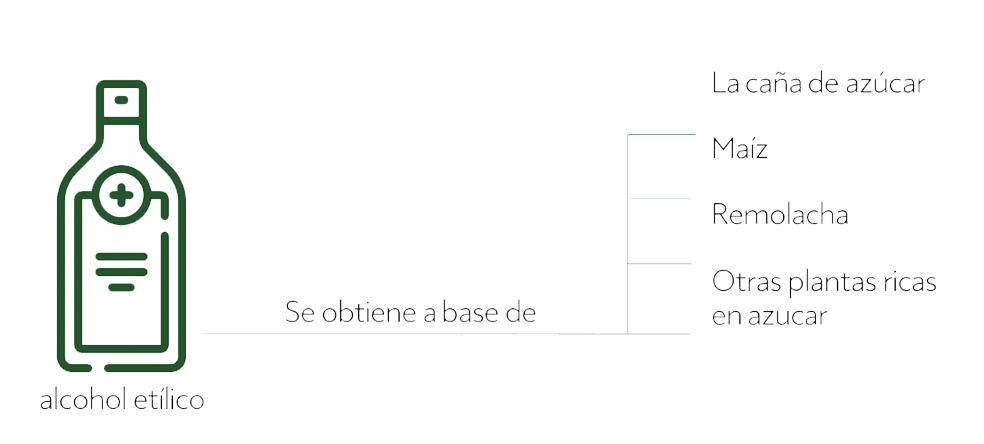

The sources for alcohol production

Ethyl alcohol can be obtained from various raw materials. The most common one is sugarcane, closely followed by corn, beets, and other sugar-rich plants. These sources contain fermentable sugars that are transformed into alcohol during the production process. Depending on the region and local conditions, the choice of raw material varies to ensure availability, profitability, and sustainability of the process.

Fermentation

Fermentation is a crucial stage in the production of ethyl alcohol because during this process, the sugars present in the raw material are converted into alcohol through the action of specific yeast or bacteria. Fermentation can be conducted under anaerobic conditions, controlling factors such as temperature and sugar concentration to achieve optimal yield. Once fermentation is completed, an alcoholic solution known as “mash”

is obtained.

Distillation

Distillation is the next step in the production of ethyl alcohol and involves separating the alcohol from the other components present in the mash, such as water and volatile compounds. This process is carried out in a distillation column, where different temperature and pressure levels are generated, enabling the selective evaporation of alcohol, which is then collected and cooled to obtain the final product with a higher concentration.

Filtration

After distillation, a filtration process is carried out to remove impurities and unwanted particles. This is achieved using specialized filters that retain undesired substances, leaving behind a clean and high-quality alcohol. Filtration can be conducted in multiple stages, depending on the quality standards required by the industry and the intended uses of the final product.

Packaging

Once high-quality ethyl alcohol is obtained, the packaging process begins. This process involves selecting suitable containers that comply with safety regulations and labelling requirements set by the industry. Packaging is conducted under controlled conditions to ensure the integrity of the product for subsequent distribution and commercialization.

Quality standards

The manufacturing of ethyl alcohol is subject to strict standards of quality and safety. Manufacturers must comply with specific regulations and standards established by competent authorities. This includes aspects such as control of alcohol concentration, product purity, traceability of raw materials, and compliance with hygiene standards and good manufacturing practices.

The use of ethyl alcohol

Ethyl alcohol has a wide variety of uses in different industries. For example, in the food industry, it is used as a solvent in the production of extracts and flavours, as well as in the preparation of alcoholic beverages. In the pharmaceutical industry, ethyl alcohol is employed as a disinfectant and as a component in the formulation of medicines and sanitizing products. Additionally, it is used in the perfumery, chemical, and cosmetics industries as a solvent and extraction agent.

Conclusión

The production of ethyl alcohol is a complex process that involves several stages, from the selection of raw materials to the packaging of the final product. Compliance with quality and safety standards is crucial to ensure high-quality alcohol that is suitable for use in different industries. The versatility of ethyl alcohol and its multiple applications in the food, pharmaceutical, perfumery, chemical, and cosmetics industries make it an essential ingredient in the business sector.

By understanding the manufacturing process and the uses of ethyl alcohol, companies can harness its potential and make informed decisions to meet the needs of their customers and markets. Providencia offers organically certified raw materials, ensuring production methods that protect communities and preserve the ecosystems in which sugarcane is cultivated.